Related Products

Caudalímetro de gas de bajo coste. No es necesario compensar la temperatura ni la presión. Tamaño máximo del sensor con diámetro DN2000. Sin piezas móvile...

El medidor de caudal Vortex mide el caudal de líquidos, gases y vapores limpios. Contáctenos para elegir el sensor de caudal adecuado y obtener un presupuesto...

El caudalímetro de turbina de gas SGW, que integra la tecnología avanzada de caudalímetros digitales para gas de China y otros países con un diseño óptimo, es una nueva generación de caudalímetros de gas de alta precisión y fiabilidad, basados en principios de neumática, hidromecánica, electromagnetismo, etc. Este caudalímetro de turbina de gas ofrece un excelente rendimiento tanto a baja como a alta presión, diversas opciones de salida de señal y baja sensibilidad a la turbulencia del fluido. Por ello, se aplica ampliamente a la medición del flujo de gas, por ejemplo, en diversas aplicaciones. Caudalímetro de gas natural, caudalímetro de nitrógeno (N2 ), caudalímetro de biogás, caudalímetro de GLP o sensor de flujo de aire industrial. SILVER AUTOMATION INSTRUMENTS es un fabricante chino de confianza de caudalímetros para turbinas de gas .

|

Medium |

Clean gas with low to medium velocity,used such as biogas flow meter,LPG gas flow meter,nitrogen gas flow sensor. |

||||

|

Standard |

Gas measurement in closed pipe-Turbine flow sensor(GB/T18940-2003) |

||||

|

Gas flow meter Size & connection |

Flange type |

Stainless steel housing |

DN25-DN300 |

||

|

Aluminum housing |

DN25,50,80,100 |

||||

|

Carbon steel |

DN350,400 |

||||

|

Thread type |

Stainless steel(non compensation) |

DN25,40,50 |

|||

|

Stainless steel(compensation) |

DN25, 40, |

||||

|

Flange |

Standard |

GB/T9113.1-2000 |

|||

|

Others |

DIN,ANSI,JIS |

||||

|

Thread |

Standard |

BSPP(male) |

|||

|

Others |

BSPP(Female),NPT.,etc. |

||||

|

Accuracy & Repeatability |

Accuracy |

±1.5%R |

±1.0%R(Option) |

||

|

Repeatability |

≤0.5% |

≤0.15% |

|||

|

Turn down ratio |

30:1-10:1 |

||||

|

Gas meter Calibration |

Facility |

1. Master Meter calibrationfacility 2. Sonic nozzle gas flow calibrationfacility 3. Bell prover gas calibration facility |

|||

|

Environment |

Temperature: 20℃ |

||||

|

Relative Humidity: 75% |

|||||

|

Working Condition |

Medium temperature: -20 ~80℃ Atmospheric pressure: 86Kpa-106Kpa Environmenttemperature:-20 ~60℃ Relative Humidity5%-90% |

||||

|

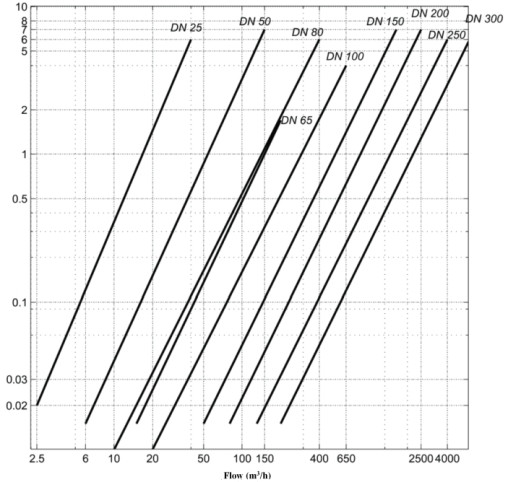

Typical Error Curve |

|

||||

Tamaño-Caudal-Caudal

|

|

|

|

Standard Flow Range |

Extended Flow Range |

|

Size (mm) |

Standard (m3/h) |

Extended (m3/h) |

Standard Pressure |

Special Pressure |

||

|

DN20 |

S |

2-20 |

W |

4-40 |

1.6Mpa |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

DN25 |

S |

2.5-25 |

W |

4-40 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN32 |

S |

4-40 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN40 |

S |

5-50 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN50 |

S1 |

6-65 |

W1 |

5-70 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

S2 |

10-100 |

W2 |

8-100 |

|||

|

DN65 |

S |

15-200 |

W |

10-200 |

Flange≤6.3Mpa |

|

|

DN80 |

S1 |

13-250 |

W |

10-160 |

Flange≤6.3Mpa |

|

|

S2 |

20-400 |

|||||

|

DN100 |

S1 |

20-400 |

W |

13-250 |

Flange≤6.3Mpa |

|

|

S2 |

32-650 |

|||||

|

DN125 |

S |

25-700 |

W |

20-800 |

Flange≤6.3Mpa |

|

|

DN150 |

S1 |

32-650 |

W |

80-1600 |

Flange≤6.3Mpa |

|

|

S2 |

50-1000 |

|||||

|

DN200 |

S1 |

80-1600 |

W |

50-1000 |

Flange≤4.0Mpa |

|

|

S2 |

130-2500 |

|||||

|

DN250 |

S1 |

130-2500 |

W |

80-1600 |

Flange≤2.5Mpa |

|

|

S2 |

200-4000 |

|||||

|

DN300 |

S |

200-4000 |

W1 |

130-2500 |

Flange≤2.5Mpa |

|

|

W2 |

320-6500 |

|||||

|

DN350 |

S |

400-8000 |

W1 |

150-4500 |

-------- |

|

|

W2 |

300-9000 |

|||||

|

DN400 |

S |

500-10000 |

W1 |

300-9000 |

-------- |

|

|

W2 |

500-10000 |

|||||

|

Model |

SGW-N |

SGW-A |

SGW-B |

SGW-C |

SGW-D |

|

Picture |

|

|

|

||

|

Display |

No Digital Display No temperature and pressure compensation |

Digital Display Instant & Totalized Flow No temperature andpressure compensation |

Digital Display Instant & Totalized Flow Temperature and pressure compensation |

||

|

Diameter |

DN20-DN400 |

||||

|

Output |

Pulse |

4-20mA |

No |

4-20mA/Pulse |

4-20mA/Pulse |

|

Power |

24VDC±15% |

Battery*1 |

24VDC±15% |

24VDC±15% & Battery |

|

|

Flow Range |

Standard |

Standard or Extended Flow range |

|||

|

RS485 |

No |

RS485 Option |

|||

|

Power consumption< 0.5W |

|||||

|

Protection level: IP65 |

|||||

*1 La duración de la batería del medidor de flujo de gas es de aproximadamente 56 meses.

| Item | Code | Description |

| General | SGW | Silver Gas turbine flow meter |

| Type | N | Without display, pulse output, 24VDC power supply |

| A | Without display ,4-20mA output, 24VDC power supply | |

| B | With display, Battery powered, without output | |

| C | With display,4-20mA output, 24VDC power supply | |

| C3 | With display, pulse output, 24VDC power supply | |

| C1 | With display, 4-20mA output,RS485,24V DC power supply | |

| D | Display, temperature and pressure compensation,4-20mA | |

| D1 | Display, T& P compensation,4-20mA,RS485 | |

| NominalDiameter | 20-400 | DN20-DN400 |

| Flow range | W(x) | Refer to table 2 |

| S(x) | Refer to table 2 | |

| Turbine Sensor Material | S | Stainless steel housing(DN25-DN300) |

| L | Aluminum housing(DN25,50,80,100) | |

| C | Carbon steel(DN350,DN400) | |

| Rotar, bearing Material | S | Corrosion Resistance ABS |

| L | Aluminium-Alloy | |

| Structure | N | Standard Structure |

| A | For Oxygen Only (O2 Only) | |

| Accuracy | 10 | ±1.0% of reading |

| 15 | ±1.5% of reading | |

| Explosion Proof | N | Non explosion proof |

| E | ExdIIBT6 | |

| Pressure Rating | N | Standard, (refer to table2) |

| H(x) | Customized,(refer to table2) | |

| Installation | FL | Flange connection |

| LW | Thread Connection *1 |

*1 Especifique el estándar de rosca del medidor de turbina al realizar el pedido; la conexión de rosca está disponible en el medidor de flujo de turbina DN20-DN50.

nos pondremos en contacto con usted en 24 horas.