Related Products

Caudalímetro de gas de bajo coste.

No es necesario compensar la temperatura ni la presión.

Tamaño máximo del sensor con diámetro DN2000.

Sin piezas móviles y de bajo mantenimiento.

El medidor de caudal Vortex mide el caudal de líquidos, gases y vapores limpios. Contáctenos para elegir el sensor de caudal adecuado y obtener un presupuesto competitivo.

El caudalímetro de turbina de gas SGW, que integra la tecnología avanzada de caudalímetros digitales para gas de China y otros países con un diseño óptimo, es una nueva generación de caudalímetros de gas de alta precisión y fiabilidad, basados en principios de neumática, hidromecánica, electromagnetismo, etc. Este caudalímetro de turbina de gas ofrece un excelente rendimiento tanto a baja como a alta presión, diversas opciones de salida de señal y baja sensibilidad a la turbulencia del fluido. Por ello, se aplica ampliamente a la medición del flujo de gas, por ejemplo, en diversas aplicaciones. Caudalímetro de gas natural, caudalímetro de nitrógeno (N2 ), caudalímetro de biogás, caudalímetro de GLP o sensor de flujo de aire industrial. SILVER AUTOMATION INSTRUMENTS es un fabricante chino de confianza de caudalímetros para turbinas de gas .

|

Medium |

Clean gas with low to medium velocity,used such as biogas flow meter,LPG gas flow meter,nitrogen gas flow sensor. |

||||

|

Standard |

Gas measurement in closed pipe-Turbine flow sensor(GB/T18940-2003) |

||||

|

Gas flow meter Size & connection |

Flange type |

Stainless steel housing |

DN25-DN300 |

||

|

Aluminum housing |

DN25,50,80,100 |

||||

|

Carbon steel |

DN350,400 |

||||

|

Thread type |

Stainless steel(non compensation) |

DN25,40,50 |

|||

|

Stainless steel(compensation) |

DN25, 40, |

||||

|

Flange |

Standard |

GB/T9113.1-2000 |

|||

|

Others |

DIN,ANSI,JIS |

||||

|

Thread |

Standard |

BSPP(male) |

|||

|

Others |

BSPP(Female),NPT.,etc. |

||||

|

Accuracy & Repeatability |

Accuracy |

±1.5%R |

±1.0%R(Option) |

||

|

Repeatability |

≤0.5% |

≤0.15% |

|||

|

Turn down ratio |

30:1-10:1 |

||||

|

Gas meter Calibration |

Facility |

1. Master Meter calibrationfacility 2. Sonic nozzle gas flow calibrationfacility 3. Bell prover gas calibration facility |

|||

|

Environment |

Temperature: 20℃ |

||||

|

Relative Humidity: 75% |

|||||

|

Working Condition |

Medium temperature: -20 ~80℃ Atmospheric pressure: 86Kpa-106Kpa Environmenttemperature:-20 ~60℃ Relative Humidity5%-90% |

||||

|

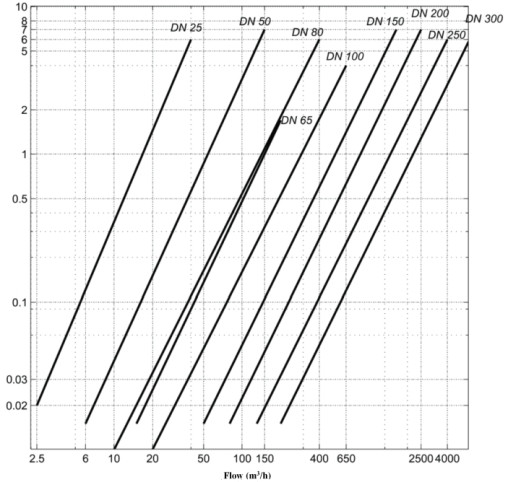

Typical Error Curve |

|

||||

Tamaño-Caudal-Caudal

|

|

|

|

Standard Flow Range |

Extended Flow Range |

|

Size (mm) |

Standard (m3/h) |

Extended (m3/h) |

Standard Pressure |

Special Pressure |

||

|

DN20 |

S |

2-20 |

W |

4-40 |

1.6Mpa |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

DN25 |

S |

2.5-25 |

W |

4-40 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN32 |

S |

4-40 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN40 |

S |

5-50 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN50 |

S1 |

6-65 |

W1 |

5-70 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

S2 |

10-100 |

W2 |

8-100 |

|||

|

DN65 |

S |

15-200 |

W |

10-200 |

Flange≤6.3Mpa |

|

|

DN80 |

S1 |

13-250 |

W |

10-160 |

Flange≤6.3Mpa |

|

|

S2 |

20-400 |

|||||

|

DN100 |

S1 |

20-400 |

W |

13-250 |

Flange≤6.3Mpa |

|

|

S2 |

32-650 |

|||||

|

DN125 |

S |

25-700 |

W |

20-800 |

Flange≤6.3Mpa |

|

|

DN150 |

S1 |

32-650 |

W |

80-1600 |

Flange≤6.3Mpa |

|

|

S2 |

50-1000 |

|||||

|

DN200 |

S1 |

80-1600 |

W |

50-1000 |

Flange≤4.0Mpa |

|

|

S2 |

130-2500 |

|||||

|

DN250 |

S1 |

130-2500 |

W |

80-1600 |

Flange≤2.5Mpa |

|

|

S2 |

200-4000 |

|||||

|

DN300 |

S |

200-4000 |

W1 |

130-2500 |

Flange≤2.5Mpa |

|

|

W2 |

320-6500 |

|||||

|

DN350 |

S |

400-8000 |

W1 |

150-4500 |

-------- |

|

|

W2 |

300-9000 |

|||||

|

DN400 |

S |

500-10000 |

W1 |

300-9000 |

-------- |

|

|

W2 |

500-10000 |

|||||

|

Model |

SGW-N |

SGW-A |

SGW-B |

SGW-C |

SGW-D |

|

Picture |

|

|

|

||

|

Display |

No Digital Display No temperature and pressure compensation |

Digital Display Instant & Totalized Flow No temperature andpressure compensation |

Digital Display Instant & Totalized Flow Temperature and pressure compensation |

||

|

Diameter |

DN20-DN400 |

||||

|

Output |

Pulse |

4-20mA |

No |

4-20mA/Pulse |

4-20mA/Pulse |

|

Power |

24VDC±15% |

Battery*1 |

24VDC±15% |

24VDC±15% & Battery |

|

|

Flow Range |

Standard |

Standard or Extended Flow range |

|||

|

RS485 |

No |

RS485 Option |

|||

|

Power consumption< 0.5W |

|||||

|

Protection level: IP65 |

|||||

*1 La duración de la batería del medidor de flujo de gas es de aproximadamente 56 meses.

| Item | Code | Description |

| General | SGW | Silver Gas turbine flow meter |

| Type | N | Without display, pulse output, 24VDC power supply |

| A | Without display ,4-20mA output, 24VDC power supply | |

| B | With display, Battery powered, without output | |

| C | With display,4-20mA output, 24VDC power supply | |

| C3 | With display, pulse output, 24VDC power supply | |

| C1 | With display, 4-20mA output,RS485,24V DC power supply | |

| D | Display, temperature and pressure compensation,4-20mA | |

| D1 | Display, T& P compensation,4-20mA,RS485 | |

| NominalDiameter | 20-400 | DN20-DN400 |

| Flow range | W(x) | Refer to table 2 |

| S(x) | Refer to table 2 | |

| Turbine Sensor Material | S | Stainless steel housing(DN25-DN300) |

| L | Aluminum housing(DN25,50,80,100) | |

| C | Carbon steel(DN350,DN400) | |

| Rotar, bearing Material | S | Corrosion Resistance ABS |

| L | Aluminium-Alloy | |

| Structure | N | Standard Structure |

| A | For Oxygen Only (O2 Only) | |

| Accuracy | 10 | ±1.0% of reading |

| 15 | ±1.5% of reading | |

| Explosion Proof | N | Non explosion proof |

| E | ExdIIBT6 | |

| Pressure Rating | N | Standard, (refer to table2) |

| H(x) | Customized,(refer to table2) | |

| Installation | FL | Flange connection |

| LW | Thread Connection *1 |

*1 Especifique el estándar de rosca del medidor de turbina al realizar el pedido; la conexión de rosca está disponible en el medidor de flujo de turbina DN20-DN50.

nos pondremos en contacto con usted en 24 horas.